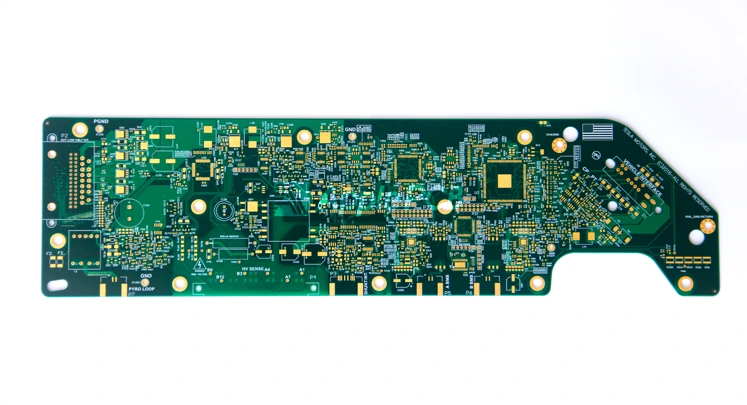

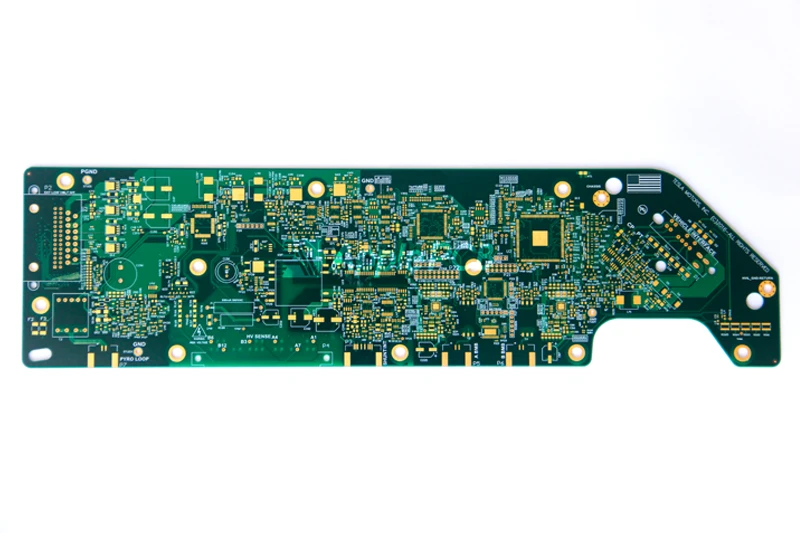

In the world of automation, the industrial pcb is the undisputed nerve center. But here is the catch: a lot of people think an industrial board is just a "sturdier" version of a commercial one. It’s not. While it might not need the exotic specs of a satellite-bound aerospace board, an industrial PCB has to be the most reliable thing in the room.

Why "Good Enough" Doesn't Cut It in the Industrial PCB

If you put a high-end commercial board on a factory floor, it’s only a matter of time before it fails. Industrial-grade performance is defined by how the board handles the "Triple Threat":

- The Environment :We aren't talking about a climate-controlled office. We’re talking about -40°C winter starts and +105°C heatwaves near heavy machinery. Factor in constant vibration and humidity, and you have a recipe for disaster for standard solder joints. Industrial PCBs are designed to absorb that stress without cracking.

- The 15-Year Marathon :Commercial electronics are built for a 3-year sprint before they're replaced. Industrial boards? They’re running a 15-year marathon—often 24 hours a day, 7 days a week. When we design for industrial pcb manufacturing, we don't just "hope" it lasts; we build in the redundancy and use the high-TG materials necessary to ensure it doesn't quit.

- The Cost of Failure :If your laptop crashes, it’s an annoyance. If an industrial PCB fails, the entire production line goes dark. We’re talking about thousands of dollars in downtime per hour, or worse—safety risks for the crew. That’s why "reliability" isn't a buzzword for us; it’s the foundation of the design.

Industrial PCB Design

Building a Reliable Foundation Before diving into the manufacturing side of industrial PCBs, we have to address the layout. A truly rugged industrial board starts with a rock-solid design. Because these boards are expected to survive years in harsh conditions, designers must anticipate potential failures long before the first prototype is made.

1.Thermal Management

The Key to Stability In the industrial world, heat is a constant threat. Proper thermal management is essential to keep a system running without interruption.

- Efficient Dissipation: Use thermal vias, dedicated heat sinks, and optimized component placement to create a clear "escape route" for heat.

- Choosing the Right Substrate: For high-power applications, standard FR4 might not cut it. Metal Core PCBs with aluminum or copper bases offer significantly better thermal conductivity.

- Smart Layout: Avoid clustering high-power components. By spreading out heat sources and placing them near ventilated areas or cooling structures, you can prevent dangerous localized hot spots.

2.Signal Integrity

Maintaining Performance in Noisy Settings Industrial environments are notoriously noisy. Keeping signals clean and efficient is one of the biggest challenges in PCB design:

- Matched Parameters: We carefully balance trace width, spacing, and stack-up thickness to optimize signal transmission.

- Smart Routing: Precise layout planning minimizes signal loss and prevents crosstalk between sensitive lines.

- Impedance Consistency: By keeping impedance uniform across the signal path, we eliminate reflections and ensure high-speed signal stability.

- Advanced Grounding: We use complete ground planes to provide a steady reference loop, which drastically cuts down on EMI and background noise.

3.Power Distribution

Ensuring a Reliable Energy Supply Industrial systems demand rock-solid power stability to function 24/7:

- Power and Ground Planes: Using heavy-duty power and ground layers helps suppress noise and keeps voltage levels consistent across the board.

- Strategic Decoupling: Placing decoupling capacitors right next to IC power pins provides a local energy buffer, filtering out sudden power spikes.

- High-Current Capacity: For high-load I/O and power zones, we beef up the trace widths to prevent voltage drops and overheating.

4.EMI Immunity

Blocking the Noise Industrial environments are filled with electromagnetic noise from motors and high-voltage equipment.

- Shielding: We use metallic shielding cans or specialized top-layer plating to block out RF interference.

- Active Filtering: Ferrite beads and capacitor filters are placed at critical entry points to stop high-frequency noise from entering the system.

- Grounding: A robust, system-wide grounding architecture is the foundation for any EMI-resistant design.

5.Mechanical Durability

Built to Last A board that flexes is a board that fails.

- Rigidity: We select board thickness based on mechanical stress to prevent warping over time.

- Shock Resistance: The layout is reinforced to handle the constant vibrations and sudden impacts common in heavy machinery, protecting every solder joint.

6.Environmental Defense

- Conformal Coating: Applying an epoxy-based coating (often called "three-proof paint" in the industry) protects the circuitry from moisture, dust, and salt spray.

- Temperature Tolerance: We use high-TG materials and industrial-grade components to ensure the board doesn't lose its physical integrity in extreme cold or heat.

Industry Standards

Designing a board that lasts a decade in a vibrating factory requires more than just good engineering—it requires strict adherence to international standards. These rules define how a board is built, tested, and validated.

IPC Class 3

For most industrial projects, IPC Class 3 is the non-negotiable standard. Unlike Class 2 (consumer electronics), Class 3 is designed for high-reliability systems where downtime is not an option. It mandates rigorous testing for:

- Thermal Stress: Surviving cycles from -65°C to 150°C.

- Mechanical Integrity: Handling 10G+ vibration and heavy physical shocks.

IPC-6012

While originally for cars, IPC-6012 is frequently used in industrial transport and heavy machinery. It sets the bar for humidity transitions and vibration profiles, ensuring the board doesn't delaminate under pressure.

IPC-A-610 & IEC-61188

- IPC-A-610 is the world's most used "visual bible" for assembly. It tells inspectors exactly what a perfect solder joint should look like.

- IEC-61188 provides the framework for layout and chemical resistance, which is vital for boards exposed to industrial solvents or gases.

UL 796

If your PCB is handling high power or needs to be sold in the North American market, UL 796 is essential. It focuses on fire safety (flame retardancy) and electrical insulation, ensuring your industrial controller doesn't become a fire hazard.

Wrapping Up

In the world of industrial PCB manufacturing, a great design is only half the battle. The true test of a manufacturer is whether they can actually execute those rigorous standards on the production line. If you’re looking for a partner you can trust, you need a manufacturer with a proven track record in the industrial sector.

With 16 years of specialized experience, ApplePCB understands that for industrial products, reliability is everything. We will precisely execute your specific requirements for thermal management, impedance control, and power distribution. Backed by a comprehensive manufacturing and testing suite, we ensure that every PCB we deliver is built to survive the toughest physical and electrical environments.