Why Are Medical PCBs So Unique? Medical PCBs specifically refer to printed circuit boards used in medical devices and instruments. They serve as core components in equipment such as monitors, ventilators, and implantable pacemakers, directly impacting diagnostic accuracy and patient safety. Therefore, medical PCBs are not merely electronic components but technological products bearing life-saving responsibilities. This article will explain the standards for medical PCBs and how to design effective medical device PCBs.

Common Standards for Medical PCBs

The manufacturing of medical device PCBs must adhere to industry standards far stricter than those for consumer electronics. Below are the three core standard systems we must rigorously follow in medical PCB production.

1.IPC Class 3

In PCB manufacturing, IPC categorizes products into three classes. The vast majority of medical devices—particularly life support systems and surgical equipment—must meet IPC Class 3 standards. This mandates zero interruptions during continuous operation.

To achieve IPC Class 3 design and manufacturing standards, our process focuses on:

- Ring Circle Precision: Inner layer ring circles must be no less than 1 mil, outer layers no less than 2 mil, with zero tolerance for broken loops to ensure absolute signal stability.

- Dielectric thickness control: Maintain a minimum dielectric thickness of at least 3.5 mils.

- Plating integrity: During medical PCB assembly, ensure through-hole copper fill rates exceed 75%, with strict prohibition of Category III copper voids.

- Trace optimization: Strictly calculate current carrying capacity and trace width according to IPC-2152 standards to prevent performance fluctuations caused by temperature rise.

2.UL Certification

Underwriters Laboratories (UL) is a global leader in product safety certification. Obtaining UL certification serves as a gateway for products to enter international markets and gain customer trust.

- UL 796: This safety standard for rigid and flexible PCBs specifies critical parameters including substrate thickness, copper foil thickness, trace spacing, and dielectric strength.

- UL 94: Material flame-retardant rating standard. Medical devices must use substrate materials compliant with appropriate flame-retardant ratings (e.g., V-0, V-1) to minimize fire risk.

- Chlorinated Traces Index (CTI): UL standards classify materials based on their resistance to electrical tracking (anti-tracking capability). For example, general-purpose FR-4 materials typically fall under Class 3 (CTI values between 175V and 249V), while high-reliability medical devices may require higher-grade materials.

Additionally, specific medical end products must comply with device-specific standards such as UL 1069 (hospital call systems) and UL 2900 (cybersecurity). PCB manufacturers selecting UL-certified raw materials constitutes best practice for streamlining the overall product certification process.

Key Considerations in Medical PCB Design

1.Component Selection: SMD or PTH?

Modern medical PCB designs generally prioritize SMDs. SMD technology significantly reduces component size and PCB footprint while increasing circuit density, offering distinct advantages for portable, wearable, or implantable medical devices. Additionally, SMT eliminates drilling, simplifying the manufacturing process and aiding in cost and quality control. However, through-hole components remain relevant. PTH components offer robust mechanical connections and higher current-carrying capacity, making them a reliable choice. Optimal designs should hybridize both technologies based on the specific requirements of the circuit module.

2.Material and Process Selection

When planning the BOM for medical PCBs, engineers must weigh the following critical dimensions:

- Compliance (RoHS Compliance): Most medical devices must strictly adhere to environmental and lead-free regulations to ensure no harmful substances are released to humans or the environment.

- Signal Integrity: Modern medical devices often integrate WiFi, Bluetooth, or high-frequency radio frequency (RF) modules, demanding exceptional dielectric constant stability from the substrate material.

- Thermal Management and Durability: Considering sterilization environments or continuous operation in implantable devices, materials must withstand extremely high maximum operating temperatures.

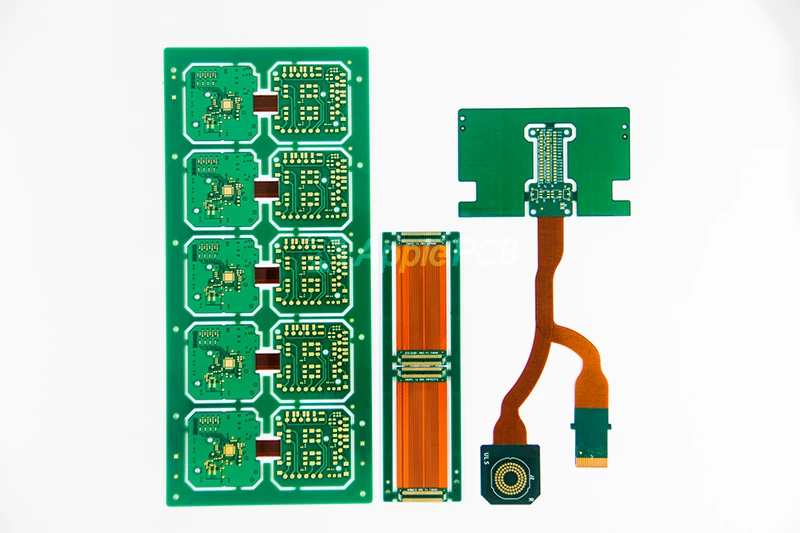

- Space Constraints: With the proliferation of wearable and portable medical devices, enclosure shapes and dimensions dictate the need for miniaturized and flexible circuit boards.

- Choosing Laminate Materials: FR-4 or High-Performance Substrates? General-purpose FR-4 materials offer high cost-effectiveness and are suitable for most low-to-mid-frequency circuits. However, for high-frequency equipment, their relatively high dielectric constant can cause signal loss. In such cases, high-performance high-frequency laminates like PTFE or ceramic-filled materials are required, as they feature more stable dielectric constants and extremely low loss factors.

Additionally, integrating high-density components (e.g., fine-pitch BGAs) often requires HDI technology. This involves processes like laser microvia and through-hole-in-pad, enabling trace widths and spacings as low as 5 mils. While this increases PCB fabrication costs, the resulting high reliability and ultra-fine trace precision are unmatched by traditional methods.

3.Lifecycle Management

Medical devices undergo lengthy certification cycles and stringent regulatory oversight. Discontinuation of a core component can force an entire product line off the market. Therefore, early collaboration with suppliers for component lifecycle forecasting is essential during design. Prioritize components with long-term supply guarantees or develop alternative solutions for critical parts to avoid triggering lengthy and costly product recertification processes due to a single component discontinuation.

4.Design for Serviceability

Exceptional medical device design embodies the principle of “designing for serviceability”:

- Clear Layout: Connectors and test points should be positioned for easy access; high-heat or large components should be distributed to prevent thermal dead zones or maintenance interference.

- Solder-Friendly Design: Pad dimensions and spacing should facilitate manual soldering or rework, especially for multi-pin devices.

- 3D Model Validation: Generate 3D PCB models using design tools to preemptively check assembly interference with enclosures, ensuring manufacturability and serviceability.

5.Test Accessibility

Test strategies must be planned during the design phase. Sufficient test points should be reserved on power supplies, critical signal lines (clocks, control signals), and interfaces. These test points serve as the device's “diagnostic windows,” greatly simplifying production debugging and field troubleshooting. A practical principle is: placing more accessible test points is far better than having nowhere to probe when needed.

6.Simulation Validation

Before building physical prototypes, simulation technology serves as the most powerful tool for predicting and optimizing performance while controlling costs.

- Signal and Power Integrity Simulation: Ensures high-speed signal quality, preventing timing errors and noise interference.

- Thermal Simulation: Identify potential “hot spots,” optimize thermal design, and prevent device performance degradation or failure due to overheating. This approach is more proactive and cost-effective than relying on post-production infrared detection.

- Digital Twin: Construct a virtual model of the circuit to simulate its behavior under various operating conditions. This enables the detection and correction of potential defects during the design phase, significantly shortening development cycles and enhancing product reliability.

From Design to Reliable Manufacturing—Solutions for Medical PCBs

In the development cycle of medical electronics, an outstanding Medical PCB Design is only half the battle. Every decision made during the design phase—from material selection to microvia placement—directly impacts the efficiency of subsequent Medical PCB Manufacturing and the reliability of the final product.

Why Is DFM Pivotal in the Medical Field?

A design for manufacturing (DFM) approach significantly reduces production risks and accelerates time-to-market. By collaborating with a specialized medical PCB manufacturer early in the design process, you ensure:

●More Efficient Medical PCB Assembly: Optimal pad design and component spacing drastically minimize soldering defects, boosting the first-pass yield of medical PCB assembly services.

●More Stable Quality Control: Designs compliant with IPC Class 3 standards facilitate stricter quality inspections during Medical PCB Board Fabrication.

●More Competitive Cost Structure: Optimized laminate solutions and process selections help you secure more advantageous Medical PCB Quotes without compromising quality.

Choose Your Trusted Medical PCB Manufacturer

Innovation in healthcare relies on high-quality hardware support. Whether you're developing cutting-edge medical instrumentation or require high-performance medical device PCB solutions, we are committed to providing comprehensive support from prototyping to mass production.

Leveraging our deep expertise in medical PCB assembly and strict adherence to global safety standards, we will help transform your medical devices from blueprints into reality, safeguarding every life and health.