In today's landscape of pervasive flexible circuits and rigid-flex boards, circuit design must prioritize not only manufacturability but, crucially, reliability. Unlike conventional rigid PCBs, flexible circuits are constantly exposed to operating stresses such as bending, twisting, and dynamic motion, making them significantly more vulnerable to abrasion, moisture ingress, chemical exposure, and physical damage. Consequently, selecting the appropriate protective layer directly determines the product's overall reliability and operational lifespan.

This critical need for robust protection is why a key material—the PCB Coverlay—has gained increasing focus among engineers. Essentially, a PCB Coverlay is a specialized protective film applied to the surface of flexible circuit boards. This article will provide an in-depth exploration of the flexible PCB Coverlay.

What is PCB Coverlay?

PCB Coverlay serves as the specialized protective encapsulation for Flexible Printed Circuit Boards. Think of it as the board’s "armored skin"—a thin, flexible membrane permanently laminated to the surface via a thermal pressing process. Typically engineered from a polyimide film coated with a high-performance adhesive, the polyimide provides essential tensile strength and mechanical flexibility, while the adhesive ensures a hermetic seal over the underlying circuitry.

Why Coverlay Is Essential For Flex PCBs

For flexible electronics, Coverlay is an indispensable component. Its critical role can be summarized by three primary functions:

1.Mechanical Protection Of Copper Traces

Flex circuits are designed for environments involving either static or dynamic bending. Bare copper is inherently delicate and prone to surface scratches, abrasion, or fatigue-induced fracturing. Coverlay acts as a high-durability buffer that absorbs mechanical stress and friction. By providing this robust physical barrier, it maintains the structural integrity of the traces even under constant or extreme folding cycles.

2.Environmental Sealing

Dust, humidity, and chemical contaminants are the "invisible killers" of delicate electronics. The adhesive layer of the Coverlay flows around the circuitry to create a total seal, effectively shielding the board from moisture ingress and atmospheric pollutants. This prevents the oxidation and corrosion that would otherwise degrade the copper over time.

3.Electrical Insulation And Signal Integrity

Beyond mechanical defense, Coverlay is a high-performance dielectric. It provides critical insulation between adjacent traces to prevent electrical shorts, thereby maintaining signal integrity and ensuring the board operates reliably throughout its lifecycle.

Types Of Flexible PCB Coverlay

1.Polyimide (PI) Coverlay

Polyimide stands as the industry standard for flexible PCBs due to its exceptional all-around performance. It offers a superior balance of thermal stability, mechanical ruggedness, and chemical resistance, allowing it to easily withstand the high temperatures of reflow soldering. Consequently, PI is the go-to choice for mission-critical applications in aerospace, automotive systems, medical instrumentation, and premium consumer electronics. As a mature technology, it is available in a wide array of thicknesses and adhesive configurations to meet specific dielectric and bend-radius requirements.

2.Polyester (PET) Coverlay

Polyester coverlay, commonly referred to as PET, serves as a budget-friendly alternative to polyimide. While it significantly reduces material costs, it still provides reliable flexibility, high dielectric strength, and excellent moisture protection. Although its thermal threshold is lower than that of polyimide, it is more than adequate for general-purpose applications. PET is typically utilized in cost-sensitive projects operating in temperate environments, such as basic consumer gadgets and low-power internal interconnects.

3.Liquid Photoimageable (LPI) Coverlay

LPI coverlay utilizes photolithography to define patterns, offering unparalleled precision and resolution. Because it is applied as a liquid, it achieves superior encapsulation of high-density, non-planar circuit topographies before being UV-cured into a uniform protective layer. This material is specifically engineered for High-Density Interconnect (HDI) flex circuits and sophisticated designs that demand tight tolerances. Its primary advantage is the ability to create much finer feature openings than are possible with traditional film-based laminates.

4.Adhesiveless Coverlay

Adhesiveless coverlay streamlines the stackup by removing the discrete adhesive layer entirely. In this configuration, the polyimide base is engineered to bond directly to the copper circuitry under heat and pressure. The result is a significantly thinner profile, enhanced thermal dissipation, and superior dimensional stability. By eliminating the adhesive, designers also remove the risk of reliability issues associated with adhesive aging or outgassing. Adhesiveless options are the ideal solution for ultra-slim, lightweight designs where every micron of thickness matters.

Key Differences Between Flexible Solder Mask And Coverlay

When designing a Flexible Printed Circuit, a critical decision is whether to specify a traditional PCB Coverlay or a liquid flexible solder mask. While both serve the fundamental purpose of protecting circuitry from oxidation and electrical shorts, they differ significantly in material composition, manufacturing workflow, and registration precision.

1.Material Composition

The physical state of these materials dictates their respective performance envelopes and mechanical properties.

- PCB Coverlay: This is a solid-state laminate composite. It typically features a polyimide (PI) base film paired with a B-stage (semi-cured) acrylic adhesive. Because it is a pre-formed film, it offers superior durability and consistent dielectric thickness.

- Flexible Solder Mask: Often referred to as flexible LPI (Liquid Photoimageable) ink, this material is a specialized liquid resin. While similar to the solder masks used on rigid boards, it is specifically formulated with added plasticizers to withstand repeated bending without cracking.

2..Application Process

The transition from raw material to a finished board involves two distinct manufacturing philosophies, impacting both lead times and assembly costs.

- PCB Coverlay (Lamination Method): Applying a Coverlay is a mechanical lamination process. Pre-fabricated sheets are aligned to the flexible PCB, then subjected to intense heat and pressure in a vacuum press. This causes the adhesive to liquefy, flow into the circuit traces, and permanently bond the PI film to the copper.

- Flexible Solder Mask(Printing Method): Applying LPI is a chemical deposition process. The liquid ink is applied via screen printing or spray coating. Once the board is pre-baked, it undergoes UV exposure and a chemical wash (development) to finalize the protective pattern.

3.Pad Opening Precision

For engineers working with High-Density Interconnects (HDI) or fine-pitch components, the method of creating pad openings is the most critical technical factor.

- PCB Coverlay(Mechanical Tooling): Openings in Coverlay must be "pre-cleared" before lamination using CNC drilling, physical dies, or laser ablation.

Design Note: Because the adhesive "bleeds" or flows slightly during lamination, Coverlay has lower registration precision. Consequently, designers must use larger solder mask clearances, making Coverlay less ideal for ultra-fine-pitch components.

- Flexible Solder Mask(Photolithography): LPI utilizes high-resolution photolithography. By using a photo-mask to block UV light, unexposed ink is precisely dissolved during development. This process allows for much tighter tolerances and finer openings, making it the preferred choice for dense, complex component layouts.

Colors For PCB Coverlay

Unlike the wide spectrum of colors available for rigid PCB solder masks, Coverlay color options are relatively limited. This is primarily due to the inherent physical properties of Polyimide (PI), the core material. In the industry, you will typically find three primary color standards: Yellow (Amber), White, and Black.

While Black and White Coverlays offer a sleek, modern aesthetic, they generally carry a higher price point than the standard Amber (Yellow) variant due to more complex manufacturing requirements. Unless your project has specific optical requirements—such as light reflection for LEDs or specific branding aesthetics—we generally recommend specifying Yellow Coverlay to optimize cost-efficiency.

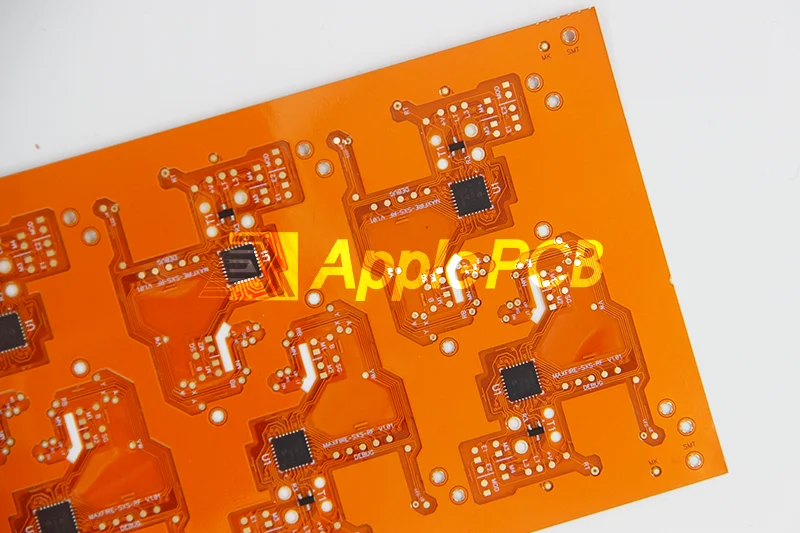

Selecting The Right PCB Coverlay Partner

Flexible cover film is a high-precision material that requires synchronized lamination with the flex circuit under stringently controlled conditions. The final performance depends on the synergy between the base substrate, the copper foil, and the lamination parameters. Any manufacturing oversight can result in delamination, registration errors, or compromised bendability.

Ultimately, choosing the right Coverlay is about choosing a manufacturer with deep expertise in flexible electronics. ApplePCB combines industry-certified materials with state-of-the-art laser cutting and vacuum lamination technology. We offer a comprehensive, one-stop solution ranging from Flex PCB Fabrication to full Turnkey PCBA.

Ready to bring your design to life? Contact ApplePCB today to kickstart your next-generation flexible PCB project!