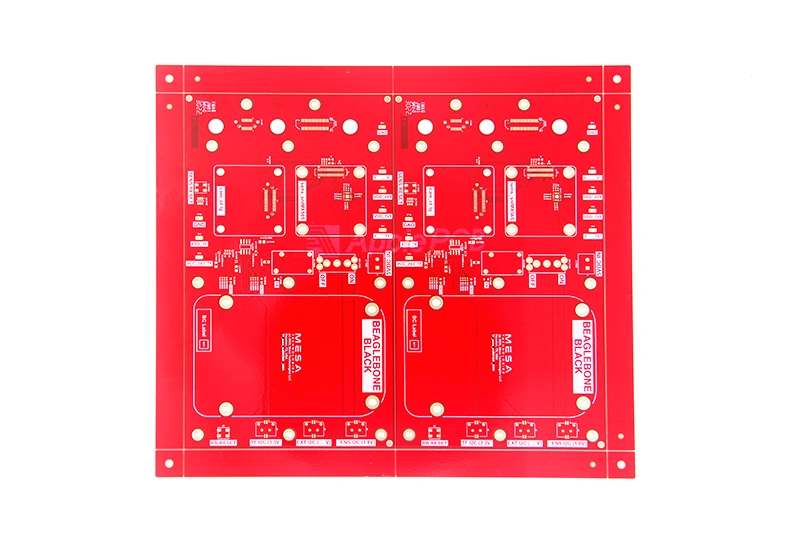

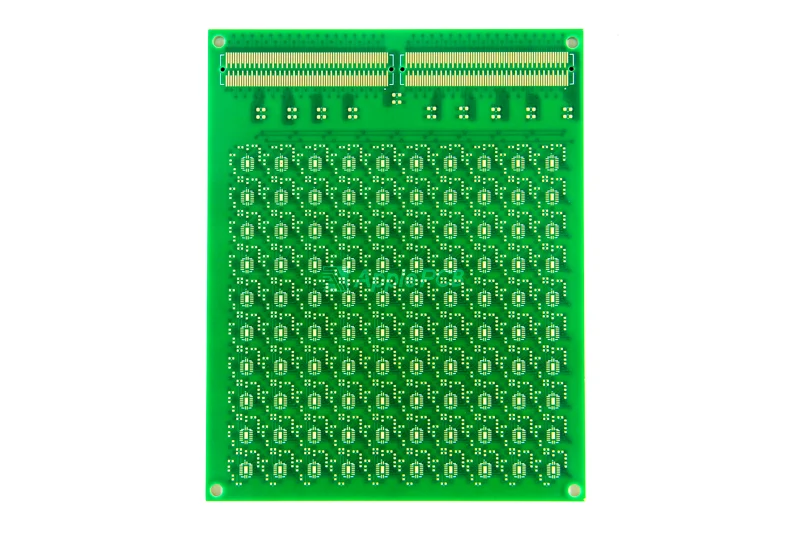

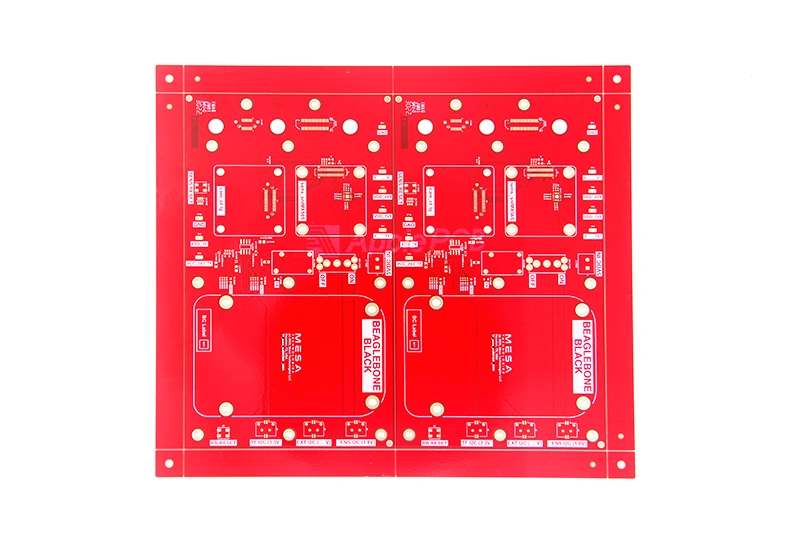

FR-4 is the most commonly used dielectric material in the manufacture of PCBs, which is made of fiberglass cloth compounded with epoxy resin, of which "FR" stands for "Flame Retardant" and "4" is the grade number of the material. So why is the FR-4 option favored by manufacturers? There are a number of reasons, and in this article we'll go into more detail so you can learn more about FR-4.

Material Properties of FR-4

Flame Retardant

FR-4 materials are able to effectively suppress the spread of flames in high-temperature environments through the addition of brominated flame retardants and other components, ensuring the safety and reliability of electronic equipment. Therefore, flame retardancy is the most distinctive feature of it.

Electrical Properties

In addition to its flame retardancy, FR-4 has excellent electrical properties. Below are some specific parameters:

| Izod impact strength at 49°C – LW | 14.00 |

| Water absorption — 24 hours | 0.10 |

| Maximum temperature | 140° Celsius (284° Fahrenheit) |

| Decomposition Temperature | >345°C |

| Flammability rating | 94V-0 |

| Flexural strength – LW -A 0.125″ | 60,000 psi |

| Tensile strength | 65,000 psi |

| Compressive strength | 38,000 psi |

| Shear strength | 21,500 psi 148 MPa |

| Bond strength | 2,300 psi 15 MPa |

| Specific gravity | 1.85 |

| Hardness, M scale | 115 |

Advantages of FR-4 for PCBs

Based on the analysis of FR-4 material properties above, it's easy to see why it has become the substrate of choice in the PCB manufacturing industry. Here are five core advantages of FR-4 PCBs:

1.Low Cost

As a standardized material, it has a mature supply chain and low cost, making it suitable for mass production. Although high Tg or high CTI and other special specifications of the model price is slightly higher, but the overall is still far lower than high-frequency materials (such as Rogers) or metal substrates, cost-effective advantage.

2.Good Electrical Insulation Properties

FR-4 has a dielectric strength of 4.25-4.55 kV/mm (affected by the way the glass fibers are woven and the resin content), which effectively resists electric field breakdown and ensures the long-term stable operation of the circuit.

3.Moisture Resistance

In humid environments, moisture absorption may lead to degradation of the electrical performance of the board and increase the risk of conductive anode filament (CAF) formation. However, it has an extremely low moisture absorption rate, which means that it is able to maintain stable electrical performance and mechanical strength in humid environments.

4.Decomposition Resistance

Decomposition temperature refers to the 5% mass loss of PCB due to temperature decomposition. FR-4 has a Td value of >345 degrees Celsius, which significantly extends the service life of PCB under extreme working conditions.

5.High Temperature Resistance

FR-4 can provide Tg values (glass transition temperature of PCB) ranging from 170. Therefore, PCBs produced with high Tg value FR-4 have excellent temperature resistance.

When Shouldn't You Use FR-4?

Despite all the benefits of this material, there are specific applications where it may not be the best choice. Below are some suggested situations to avoid using it:

1.High Thermal Requirements

The low thermal conductivity of FR-4 makes it difficult for heat to dissipate quickly. In applications with high power density or where rapid heat dissipation is required, the use of it may result in high temperatures that may affect component performance or life. In this case, it is recommended to use materials with higher thermal conductivity, such as aluminum or ceramic substrates.

2.Lead-Free Soldering Process

Lead-free soldering processes require higher soldering temperatures. Standard FR-4 has a lower glass transition temperature and may be deformed or damaged during the soldering process. Therefore, it is recommended to use high Tg FR-4 or other materials with higher temperature resistance in lead-free soldering applications.

3.High Frequency Signal Transmission

It has a high dielectric constant (Dk) and loss factor (Df), typically 0.020 (tan(δ)) @ 1GHz, which results in high signal loss during high-frequency signal transmission, affecting signal integrity. For high frequency applications, it is recommended to use materials with low dielectric constants and low loss factors, such as the Rogers family of high frequency materials.

Final Thoughts

With this information in mind, if you are still confused as to whether to continue using FR-4, or to choose another material such as Rogers, ceramic or metal substrates, ApplePCB can provide you with professional advice and support. As a Chinese PCB manufacturer with over 15 years of experience, we are committed to helping our customers choose the material that best suits their product needs, thereby reducing project complexity and cost. Contact us today for a quote or help with product selection.